Supply chains must meet multiple objectives: a high level of customer fulfillment, profitability targets, and resilience to disruptions. Companies are also beginning to prepare their supply chains for a responsible future by guaranteeing that their production and transportation systems are safe and environmentally friendly, raw materials are obtained from sustainable sources, and workers are paid fair wages. Until recently, the cost of achieving all these goals was exorbitant, forcing organizations to make tradeoffs. However, analytics combined with Internet of Things (IoT) and blockchain technology are rapidly making these objectives attainable.

My research has shown that blockchain can greatly improve the performance of supply chains. But capturing its potential for doing so requires new permissioned blockchains (i.e., blockchains in which participation is restricted to known supply chain partners), data standards, and governance rules.

Capabilities to Develop

Firms should take four types of steps to strengthen their supply chains, but they should be patient; the execution of these steps and realization of gains will take time.

1. Add IoT and tracking functionality.

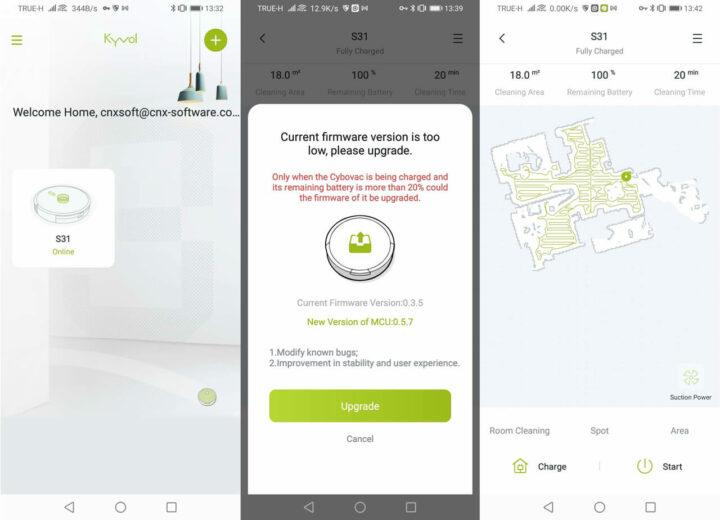

Organizations should equip their supply chains with IoT functionality and the ability to track individual units of components and finished-goods inventory. In simple terms, IoT refers to the capability of machines to use sensors to automatically collect data such as temperature, pressure, GPS location, and bar code scans, and to autonomously upload this data to a cloud server via the internet.

IoT enables organizations to collect new types of data from different stages of their supply chain. For example, such devices can track the production of a packaged food product from the sourcing of ingredients to production, shipment, and retail, including the condition of inventory and working conditions in manufacturing and logistics facilities.

Insight Center CollectionTaking on Digital Transformation

Moving your company forward in the wake of the pandemic.In some industries, laws and regulations — such as the Food Safety Modernization Act (2011) and the Drug Supply Chain Security Act (2013) in the United States and the Falsified Medicines Directive (2013) and the European Green Deal in Europe — will soon require companies to trace the movement of their products, keep records of that movement to show proof of identity, and measure the environmental impact of activities throughout the supply chain. Data collection is the first critical step toward achieving these goals.

2. Record transaction data.

Organizations should record transaction data from IoT devices on a blockchain, which can capture extremely detailed decentralized data and can be used to verify that transaction records are authentic. A firm can utilize this data to ensure sustainable sourcing, improve the execution of supply chain contracts, and gain better financing.

Since the implementation of a blockchain-based system can be done in a decentralized step-by-step fashion, it does not require large investments in information technology systems or costly third-party certification.

3. Standardize and align data from different sources.

This is necessary to use data collected from the IoT devices in a supply chain.

Suppose a firm uses temperature sensors in a fulfillment center to record storage temperature every hour and inventory scanners to track the movement of inventory into and out of the fulfillment center. The firm needs to align these data tables together to learn what units of inventory were stored at what temperature for what duration.

Here’s another example. When a consumer products firm uses blockchain to source palm oil from sustainable deforestation-free farming, the unit of data collection changes across the supply chain from palm fruit to oil to derivative products to finished consumer items. Data at each stage is combined with the bill of materials to completely trace the inputs in each batch of finished products. Doing so requires capabilities in data storage, interpolation of missing values, and descriptive analytics.

4. Develop predictive and prescriptive analytics.

For example, temperature data from fulfillment centers can be utilized to predict how soon a food product will ripen or spoil. This predictive model can then be used to guide inventory planning and design promotions for soon-to-be-spoiled food products. Doing so will improve profitability and reduce food waste.

Ripe.io, an agri-tech organization, used traceability data from tomato production to relate the flavor of ripened tomatoes to growing conditions. Predictive analytics enabled the firm to grow different types of tomatoes according to the needs of different customer segments.

Another organization, Dibiz, which is a blockchain platform for the sustainable sourcing of palm oil, discovered that data for smallholder farmers, which its platform made visible to all the members of its supply chain, enabled dealers and mills to optimize pickup routes based on real-time fruit harvests. This reduced logistics cost, benefiting farmers and mills. In addition, it improved the quality of the fruit reaching mills, which resulted in a higher (in terms of amount) oil-extraction rate, reducing the risk of deforestation and generating higher returns for farmers. (Disclosure: I am on Dibiz’s advisory board and own a small amount of its stock options.)

Where to Begin

It’s not necessary for an organization to develop all four capabilities simultaneously. It can develop them in any sequence and at any scale.

For example, a firm may start recording existing transaction data on a blockchain and using it to trace the movement of units before it invests in IoT devices to collect new data. Alternatively, the firm may start using IoT devices and analytics before acquiring blockchain technology. Indeed, these capabilities are complementary: Each makes it more viable and fruitful to develop the others. Therefore, even small investments in IoT technology, blockchain, and analytics can offer significant rewards in the long run.

How to Measure Success

The gains obtained from blockchain, IoT devices, and analytics can be viewed as a hierarchy.

At a foundational level, the source of value generation most quickly reaped is from reducing execution errors and improving productivity through visibility, traceability, and the automation of supply chain tasks. This benefit — which is especially useful in the pharmaceutical, food, and shipping industries — can be realized very quickly because it can be obtained simply by collecting and recording data that was previously hidden; it does not require further analytics. For example, Walmart Canada and DLT Labs used IoT data and blockchain to improve the accuracy of billing for third-party trucking logistics providers. They reduced billing disputes from 70% to less than 5%, resulting in significant cost savings and faster disbursement of payments.

The next level of gains is based on predictive analytics and optimization applied to the collected data. Such applications take longer to develop but can be of great value. The Ripe.io and Dibiz examples I described fall into this category.

In addition, applications of this type are possible in areas such as closed-loop supply chains in which manufacturers are responsible for collecting used products from consumers and recycling or salvaging them in safe and environmentally friendly ways, tracking the greenhouse gases used at every point in the supply chain, and reducing food waste. For example, normally it is impossible to distinguish batches of perishable food products from each other in a fulfillment center. But if each batch is tracked individually, its remaining shelf life can be computed, and this data can be used as an input to design new algorithms for allocating inventory to retail stores, soup kitchens, and food pantries.

The biggest potential source of gain is utilizing data and analytics to create new products and services such as building new marketplaces that use blockchain data to match buyers and sellers, writing more efficient contracts that take advantage of a blockchain-based system’s ability to measure effort and performance more easily, and taking advantage of the visibility of activities across the layers of the supply chain to create customized products.

As a result of these advances, supply chains may ultimately be more environmentally friendly and provide better wages, safety from contamination, and more transparency to all the members of the supply chain and consumers.