In today’s world, devices are more connected than people. Whether it’s the smartwatch on your wrist, or the voice assistants that we are becoming highly dependent on, the gadgets around us make our lives easier by working coherently. This is all possible due to the concept known as IoT, which can greatly impact procurement teams.

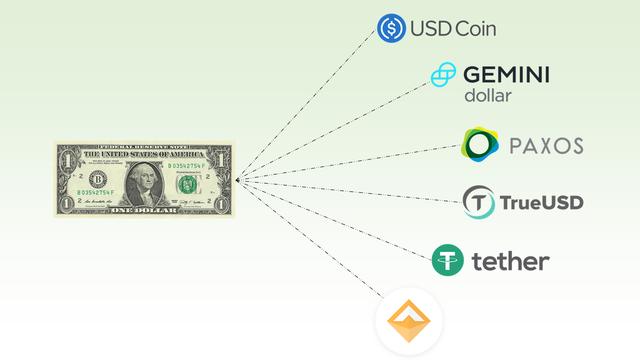

'IoT will bring greater spend visibility and a better understanding of supply and equipment utilization for procurement.' - Kissflow Procurement CloudClick To TweetThe internet of things, or IoT, is a network of interconnected computing devices, mechanical and digital machines, and people with unique identities (UIDs). This offers the capacity to transfer data without needing human-to-human or human-to-computer contact. Instead, this communication is possible via networks and cloud-based systems.

An IoT ecosystem is made up of web-enabled smart devices that gather, send, and act on data from their surroundings using embedded systems such as CPUs, sensors, and communication hardware.

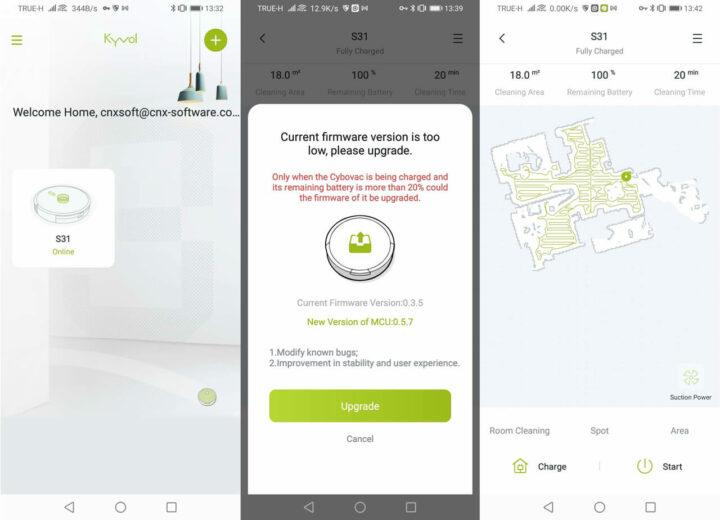

By connecting to an IoT gateway or other edge device, IoT devices may exchange sensor data that is either routed to the cloud for analysis or examined locally. In addition, these gadgets sometimes connect with other related devices and act on the information they receive from one another. Although individuals may engage with the devices for the initial setup, give instructions, or retrieve data, the gadgets perform most of the work without human involvement.

The Role ofIoT in Procurement

Procurement acts as an integral part of business. It necessitates the procurement teams to implement new technologies in order to boost productivity, improve customer service, and save costs. From trends shifting to automation in procurement, IoT in procurement is the next big thing in the era of digital transformation.

The Internet of Things will bring greater spend visibility and a better understanding of supply and equipment utilization for procurement. By understanding precisely what is being utilized and what is required, your procurement team will be able to optimize catalogs and manage spending. The capacity to foresee demands more precisely through analytics can significantly improve budget and contract management. Moreover, data generated through IoT sensors and other devices can help make informed decisions.

Let’s look at several ways in which IoT works in procurement.

Traceability of Materials

A McKinsey Global Institute study indicated that by 2025, the Internet of Things’ potential contributions to inventory management, supply chain management, and logistics might be worth between $560 billion and $850 billion per year.

This is a shocking number. The way IoT contributes to these above aspects is often through the use of tracking. IoT sensors can significantly contribute to an effective inventory management system. For example, RFID tags combined with IoT devices track physical inventories while eliminating the need to scan barcodes or labels.Additionally, businesses can track the days before items expire using interconnected IoT devices, which is particularly valuable when a company has a vast inventory, and there’s a threat that the products may expire. Alerting the management regarding the due dates saves inventory from being discarded as waste.

IoT also aids in the prevention of product theft by allowing businesses to track the whereabouts of their items. Moreover, with the help of machine learning, procurement teams can arrange products per demand.

Supply Chain Visibility

Supply chain visibility, in which items are documented as they travel from the manufacturer to the customer, is another way in which IoT technology may be successfully leveraged in procurement.

An IoT system may read data from various devices, including smart tags (RFIDs and Barcodes), as well as sensory data such as ambient temperature and humidity, vehicle speed, and geolocation, and can efficiently follow the supply chain when coupled.

The use of IoT devices to track inventory and route planning can help determine where and when items are delayed in transit. This facilitates emergency planning and the identification of alternate ways to speed up the supply chain.

Stock Management

In addition to smart shelves and storage bins that transmit stock levels in real-time and tell how long inventory has been on the shelf, IoT can aid in the identification of consumption patterns.

For example, if Product A on Shelf X has been one of the fastest utilized items, IoT sensors will detect the rate of usage of that item and suggest its economic order quantity (EOQ). This explains how critical procuring an item is for the business and which products need to be procured at what quantity. Procuring an ideal inventory quantity helps reduce costs by minimizing waste and the threat of shortage.

Using IoT devices helps determine the lead times required to assemble all of the parts required for production. Excessive lead times are recognized in order to minimize bottlenecks created by the absence of crucial parts, which can halt the manufacturing process.

Monitor and Alert Maintenance

The danger of sudden equipment breakdown can threaten the smooth operations of a business. If the condition of the equipment is unknown, this can result in process disruption, unscheduled downtime, and even lost income.

Condition monitoring through IoT sensors allows teams to observe indicators such as temperature, vibration, oil, and performance analysis. When these indicators are out of range, IoT sensors notify teams via computers. Alerts regarding these deviations tell when equipment needs a basic check or is on the verge of failing. When maintenance is scheduled as soon as a possible problem is identified, the likelihood of downtime is considerably decreased, ensuring that operations remain productive.

Better Decision Making With Predictive Data Analytics

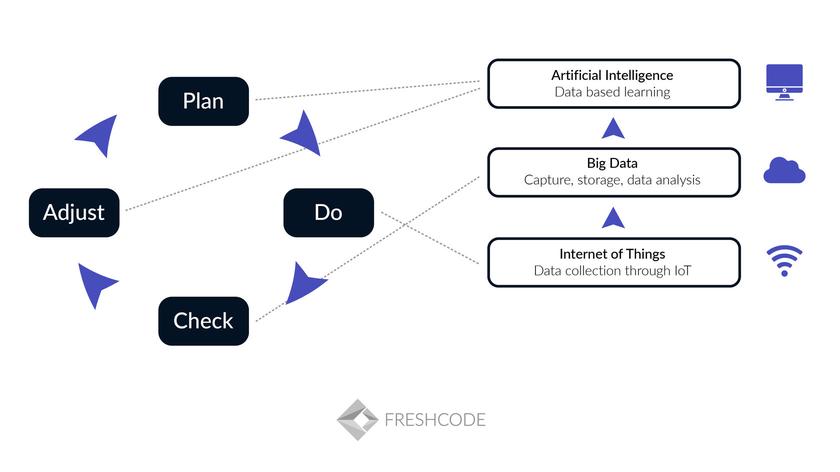

Through both predictive data analytics and spend analytics, procurement teams can make predictions about the future. These predictions can help with critical decisions regarding designing and implementing business strategies. Continuously gathering data with IoT devices aids in the creation of more robust and relevant historical data. In addition, combining IoT data with additional data from other sources can help businesses to grow more.

For example, having information on what quantity of a product is being used can help in sending accurate requisitions for approvals and generating error-free purchase orders. This leads to an efficient purchase management system. Data gathered by IoT may also be utilized to onboard suppliers with the support of supplier management solutions for new products based on prior performance metrics and set criteria.

IoT Procurement Takeaway

The Internet of Things is moving faster than we ever imagined. As a result, additional investment in this technology and advanced technology initiatives is required. Procurement teams need a complete IoT framework, machine learning, artificial intelligence, and embedded technologies in today’s interconnected world. These technologies have the potential to enhance multiple business activities and functions.