Technology has always remained the most prominent disrupting force across sectors, and the supply chain industry has been no exception. Technology is rapidly disrupting the supply chain industry across levels, from last-mile delivery to providing sustainability solutions to automated processes and tailor-made software at warehouses.

In today's world, where almost every sector is struggling to recover from COVID-19, India is emerging as a hotbed for opportunities for the Internet-of-things (IoT) which is set to soar to roughly $15 billion by 2021, as per the Zinnov report. The Increased penetration of affordable devices, combined with the power of cloud computing, analytics, and rising consumer expectations, is laying out the path for the rapid growth of the IoT market. With commerce getting more intelligent, the supply chain industry is expected to grow increasingly dependent on IoT, offering to adopt a data-driven approach as required by businesses today.

Simply put, IoT refers to a network of connected devices, objects, and sensors that accumulates data and communicates information. Applying IoT concepts to the supply chain environment has led to the rise of Industry 4.0, epitomizing innovative processes and smart services, aiding the industry transition towards an increasingly decentralized and self-regulated model. As businesses pivot from response to recovery post-COVID-19, end-to-end visibility has become imperative. Combatting this requires prescriptive analytics backed by real-time data from across physical fronts to avoid expensive disruptions, and IoT satisfies this need by faithfully refurbishing the entire supply chain environment.

The research report by HERE Technologies suggests that around 56 per cent of logistics companies are already using map-based solutions with real-time location data for shipment monitoring. IoT has started gaining momentum in fleet management, with 11 per cent of logistic companies currently using it. In the next two years, 38 per cent of companies are expected to channel more investments into IoT, while 29 per cent and 10 per cent show high interest in warehouse automation and electric vehicles, respectively.

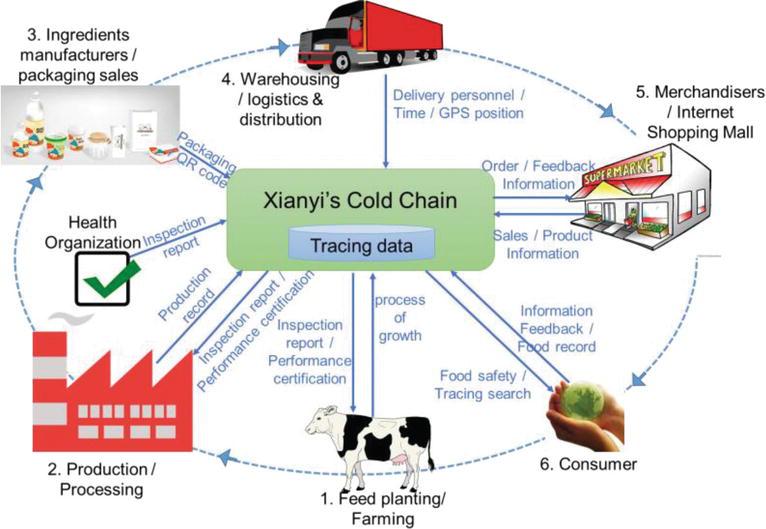

IoT gathers multiple data elements such as the temperature inside containers, pressure, humidity, and other factors that could potentially compromise the product's integrity to trigger automatic condition adjustments. Real-time information gathered across IoT devices offers decision-makers a crystal-clear picture of everything: right from customer orders to individual items moving through the supply chain. This helps in optimizing the overall operating cost. IoT thus not only facilitates the tracking and monitoring of goods but also increases the precision of planning and brings more transparency to the communication process, thereby instituting a value creation approach in the sector.

With environmental sensors in place, organizations can now monitor storage conditions and track shipments in real-time whilst swiftly responding to incongruity and divergences. Global brands such as Amazon, Volvo, Nissan are pushing their frontier by placing IoT in their supply chain ecosystem. Shipping and logistics services giants like Maersk are piloting a Remote container management system that monitors the temperature and humidity in shipping containers, whereby an alarm is triggered if set limits are breached. This helps in reducing food spoilage and resource wastage while ensuring the quality of goods. The platform thus enables operators to monitor environmental conditions and improve the precision of transportation planning and implementation.

Besides movement, IoT also facilitates tracking the speed and the traffic flow, thereby enhancing how goods will move through the supply chain. This enables manufacturers, suppliers and distribution centres to map and plan shipments effectively to reduce handling time while ensuring efficient processing of materials.

IoT is today empowering organizations by offering them enhanced visibility into disruptions and calling for their attention early on in time. The case is not just true for the big players but also for the small and mid-scale organizations. With quicker detection of changing conditions, organizations can pivot faster decisions, improving business continuity. Additionally, with access to real-time information about every phase of operation, organizations can now see and respond to disruptions well in time.

Way forward

The idea of specialized and integrated AI-driven supply chains and logistics could be new to India; however, they are being rapidly adopted by new-age e-logistics players on a large scale, especially by the small industries. The reason - it is what business rationale counsels as the logical way forward.

With technology stored and deployed in the cloud, real-time tracking becomes more accessible and faster for all stakeholders connected to the modern-day supply chain and logistics ecosystem. IoT provides much deeper insights into individual processes, thus offering decision-makers a holistic 360-degree view of the business.

Like any digital transformation effort, the future of supply chain management is not at the mercy of any single technology but rather an amalgamation of capabilities to realize specific business goals. Digital disruption has already made in-roads into the industry in the form of digital freight forwarding, with traditional approaches now being gradually shunned. Therefore, if one is eyeing to address and solve specific business challenges, the optimized and most efficient solution will probably encompass the integration of technologies - IoT, real-time data streams, enterprise planning engines, AI, and advanced analytics.