Loopworm, a Bengaluru-based agri-biotech startup, is engaged in the farming of Black Soldier Fly (BSF) Larvae that converts food waste to produce premium animal feed and pet food.

Founded right out of college by IIT-Roorkee alumni Ankit Alok Bagaria (dual degree-Chemical Engineering) and Abhi Gawri (B.Tech-Electrical Engineering) in September 2019, Loopworm today creates an “extremely protein-rich diet” for fisheries and poultry farms by “farming insects to feed them using food waste which currently lands in landfills”.

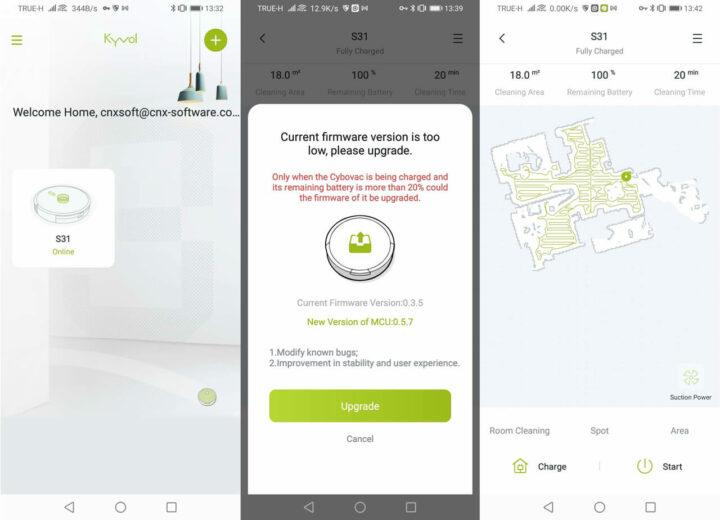

Feature Image: Loopworm co-founders Ankit Alok Bagaria and Abhi Gawri (left)

AdvertisementThe insect larvae feed on rejected food and accumulate healthy protein and fats, excellent for omnivorous and carnivorous species. At the same time, a lesser-known facet of this process is that the food rejected is also converted to a plant immunity-enhancing soil additive as well.

“Today, there is a scarce supply of wild marine fish required to make fishmeal and land required to grow soya for the soy meal for animals. Loopworm’s insect protein solves this problem and provides the right alternative protein source for pets, fish, shrimps, chicken and pigs. We are a group of passionate IITians on a mission to revolutionise the feed industry by creating a high-grade insect-based sustainable protein for poultry, aquaculture and pets,” says Abhi.

To achieve their objective, the young Loopworm team have developed an indoors, vertical smart insect breeding, production and processing technology to produce sustainable BSF larvae based protein and fats for aquaculture, poultry, pigs, and pet food.

AdvertisementStarting Out

Ankit and Abhi first met in 2017 at the IIT-Roorkee student chapter of Enactus (Entrepreneurial Action for Us), which promotes university students towards social entrepreneurship. They connected over their shared interest in social entrepreneurship – more specifically waste management. In college, they would end up working on multiple waste management projects.

“That’s where we came across the fact that 50% of waste in India is food waste. Mind you, we are just talking about post-consumer waste (food purchased by a consumer and subsequently not eaten) and doesn’t include pre-consumer food waste from the food processing industry, agri-processing industries, expired food material or food that has gone to waste because of transportation and storage issues,” says Ankit, speaking to The Better India.

AdvertisementWhat they wanted was to make food waste a positive value resource and bring it back into the food chain or the ‘food loop’. That desire shaped their decision to establish Loopworm.

“We also came across this eye-opening report from the United Nations published in 2014 which stated that insects are the future of food and feed. There are communities around the world that consume insects. After reading the report and extensive online research, we found that there are already companies in the West capitalizing on this concept where insects actually consume food waste/reject. These insects are then very rich in protein, fats and other nutrients, following which they can be used to feed animals and eventually humans too,” he says.

Arriving at BSF Larvae

AdvertisementTo the uninitiated, the BSF, which is also known by its scientific name Hermetia Illucens (Linnaeus), is a sleek looking tropical fly that holds some unique properties.

“Their larvae break down organic substrates and return nutrients to the soil. The larvae are voracious eaters of food rejects and grow 3,000 times in just 10 days. They are packed with approximately 40% proteins, rich in essential amino acids and 30% fats, rich in Omega 3,6 and 9 fatty acids,” notes a Loopworm document accessed by The Better India.

In addition, “they have antibacterial properties and are rich in anti-microbial peptides and high digestible calcium, ensuring good growth and immunity of pets and farmed animals,” the document adds.

AdvertisementBut before arriving at the BSF larvae as a solution, Ankit and Abhi started with mealworms, which they discovered posed their own challenges.

“There are several insects in the ‘Insects as Food and Feed’ domain which includes the BSF, mealworms, crickets, grasshoppers, etc. Each insect here presents their own challenges. With crickets and grasshoppers, it’s very difficult to contain them in a controlled farm environment. Also, these insects are regarded as pests as grasshoppers can damage your plants and crickets can be very invasive in nature. Mealworms, for example, are common pests in granaries. With India being an agrarian country, it’s very risky to grow these pests,” says Ankit.

“But the BSF Larvae has proven to be a non-pest and non-invasive insect. It doesn’t have any stinging or biting capabilities. The fly doesn’t require any food and only survives on water. Its primary purpose is to mate. These flies mate, lay eggs and die. The larvae of these flies are voracious eaters of food waste. You can control the larvae in a farm environment, unlike crickets or grasshoppers. They aren’t considered pests and cannot harm you like other insects like honey bees, for example. It’s safe to grow and nurture them in our local ecosystems,” he adds.

AdvertisementThese insects are social. If you try to catch a BSF in your hand, it won’t try to get away. Thus, it’s easy to train people to catch them.

“Also, the BSF Larvae is a tropical insect, completely safe and harmless to humans, animals, and plants. Our BSF culture is hygienically produced, reared on probiotics treated food industry by-products and contaminants free,” adds Abhi.

The Process

AdvertisementAccording to the World Bank, approximately 90% of global marine fish stocks are now fully exploited or overfished, while 85% of the land is already utilised. Loopworm has factored in these statistics, coupled with the fact that the growing demand for fishmeal and soymeal have resulted in their prices increasing by almost four times. And these prices shall continue to rise. There is an urgent need for alternatives.

With insects being the closest form of the natural diet of smaller fishes, they provide the best amino acid profiles and micronutrients required for the maximum growth of fishes. Meanwhile, studies show that poultry is gradually turning resistant to antibiotics due to the additional supplements. Going further, “Studies have [also] shown that with insect protein as an additional supplement, allergies have dropped drastically due to the strong antioxidant properties of the BSF larvae,” notes an internal Loopworm document shared with The Better India.

Related Stories ‘100% Life, 0% Marks’: Dhimant Parekh Shares How The Better Academy Can Help You GrowAfter Contracting UTI, Woman Innovates Spray that Prevents Infection & Saves 55% WaterAdvertisementSo, how much food waste does Loopworm convert using the BSF Larvae? Their focus currently is on pre-consumer food waste. Today, the Bengaluru startup deals with microbreweries and bread manufacturers in Bengaluru, from where they obtain spent grains (leftover grains after the beer has been manufactured), expired bread and bread rejects.

“On a weekly basis, we get close to 500 kgs of expired bread and 500 kgs of spent grains as well. Every type of waste has a different moisture content. The BSF Larvae prefers a moisture content of about 70%. So, we actually mix some water into the bread waste to obtain more substrate for the insects. Currently, we are doing close to 1.5 tonnes of live insects, which in itself has about 70% moisture. The process includes getting them cleaned, degutted, euthanizing them properly and then extracting them with the help of an ‘expeller’,” says Ankit.

How does the ‘expeller’ work? For example, you have oil seeds. To extract oil from it, you grind it and applying mechanical and thermal pressure energy you squeeze the oil out of it. That is something we do with our insects as well but the parameters are different. The insects are not that hard and the protein can actually get corroded if you expose it to too much heat. You have to use similar technology, but the operating parameters become different,” he adds.

Backed by its own processes, Loopworm has thus far introduced four products:

Defatted Dried BSF Larvae Protein Powder: It is a solvent-free extraction of fats from the larvae without denaturing the protein to produce a protein concentrate ideal for inclusion in animal feeds as a replacement for soymeal or fishmeal.

Whole Dried BSF Larvae: “The dried larvae are a good replacement of live insects in the natural diets of fish, birds, turtles, and crustaceans,” says the document.

Insect Oil: Loopworm’s insect oil is a natural fat derived from the larvae of the BSF.

“Our product is a natural food source for animals and helps promote their health naturally and sustainably. The oil also has a huge potential in the cosmetic industry,” notes Ankit.

Insect Frass: The larvae of the BSF produce an effective, natural and certified organic fertilizer.

“The slow-release fertilizer contains high organic matter and bioavailable nitrogen. It contains no artificial chemicals and can be used after drying and milling. This fertilizer contains a nutrient-dense blend of N-P-K and minerals, which promotes strong plant growth and triggers natural defence mechanisms to deter unwanted pests,” explains the document.

Thus far, their primary market is pet foods. According to Ankit, 80% of India feeds their dogs with home-based foods, while the other 20% is made up of brands like Pedigree or Harrier. When it comes to home food, Indians are predominantly carbohydrate consuming people.

“There isn’t a lot of protein in our diets. But the way you consume food is very different from a dog. See, dog food has to be bland. You cannot add a lot of salt and masalas to it. So, when you’re feeding them home-cooked food, you have to cook specially for dogs. And that becomes challenging in the urban ecosystem where a lot of these families just don’t have the time. Cooking especially for a dog becomes difficult,” he explains.

“Insect protein is sustainable, hypoallergenic, and a lean source of animal-based protein. It offers high digestibility, a superior amino acid profile, and supports cartilage and bone growth. As a brand, we are currently not catering directly to the consumers/pet parents yet. What we are propagating is that you can add insect protein powder which smells like peanuts and tastes very malty and add that to a home-cooked khichdi, bread or roti (common food items in Indian kitchens). We are focussing on convincing food and pet feed manufacturers and pet supplement manufacturers to start utilising insect protein and fats as ingredients in their products. The objective here is to make our mark in the B2B segment before venturing into B2C,” says Abhi.

In other words, what Loopworm is trying to achieve is first make a mark in the pet food market, generate the necessary volumes and establish a sustainable business model.

At the same time, they are out to prove to the feed community that they can offer things like increasing the immunity in farm animals, increasing their growth rates and enhancing meat/feed quality with their products. “Once we have proven these things, we can charge a premium,” says Ankit.

Funding, Looking Ahead

Ankit and Abhi started Loopworm by investing some of their own money and gradually focussed on obtaining government grants that are equity and debt-free. “Till date, we have been able to secure grants worth Rs 1 crore from the Union and Karnataka government, of which Rs 50 lakh has reached us so far. We also received support from Social Alpha (a venture development platform for science and technology startups), who have been with us since 2019. We are seeking equity funding and in the process of getting investors on board,” says Ankit.

Loopworm is not just a farming business, but a biotechnology venture because it has elements of life sciences. “The way you prepare the feedstock for insects matters a lot and the way you process them also matters. We have actually spent all this time proving our concept,” he adds.

They are not keen on setting up massive factories but outsourcing the technology they have developed for an indoor vertical farm to progressive farmers and others trying to create additional income streams. Besides, the Bengaluru-based venture is also planning to scale the capacity of consumption of food and agri waste to 140 Tonnes per week (20 TPD) in 6 months’ time, while working with 10 farmers who will run decentralised larvae rearing units. These decentralised larvae rearing units are planned to be set up around the city.

“They can set up a small 1,000 sq feet insect farming unit, and we would provide them with insect seed culture, feedstock, etc. They simply have to rear these insects and we will purchase them back. So, it is very similar to the integrated broiler poultry model which is out there perfected by companies like Suguna and Venky’s,” he says.

(Edited by Vinayak Hegde)